Plan and Manage Your Journey to Net-Zero

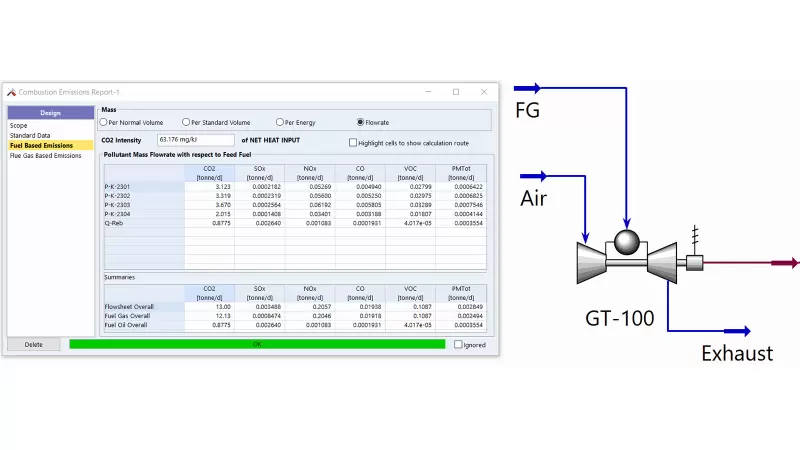

Industries are under tremendous pressure to reduce their greenhouse emissions. The goal to achieve net zero is 2050. Various governments, to some degree, are penalizing companies that do not meet standards. However, engineers struggle to predict the behavior of their production and processing assets from the point of view of energy and emissions reduction management at the right level of accuracy and with the right level of detail. This causes the adoption of suboptimal strategies for energy usage optimization, emissions reduction, carbon capture, utilization, and storage (CCUS) projects.

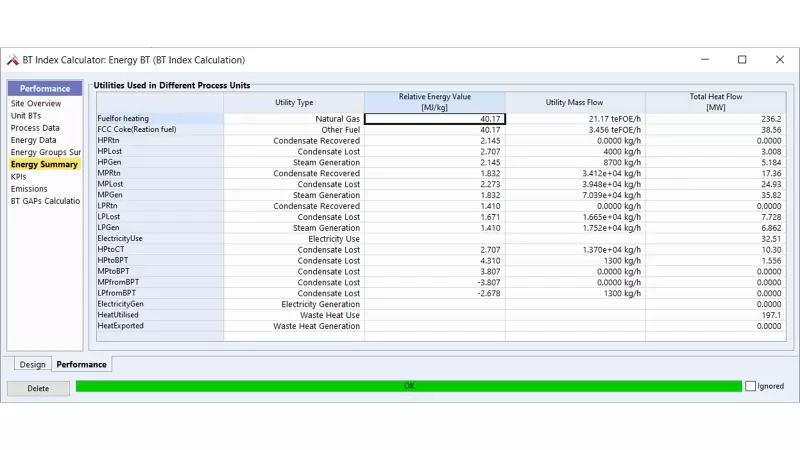

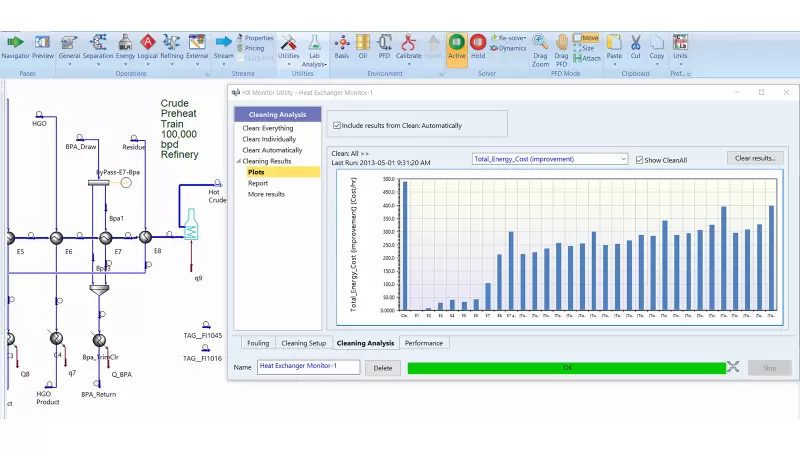

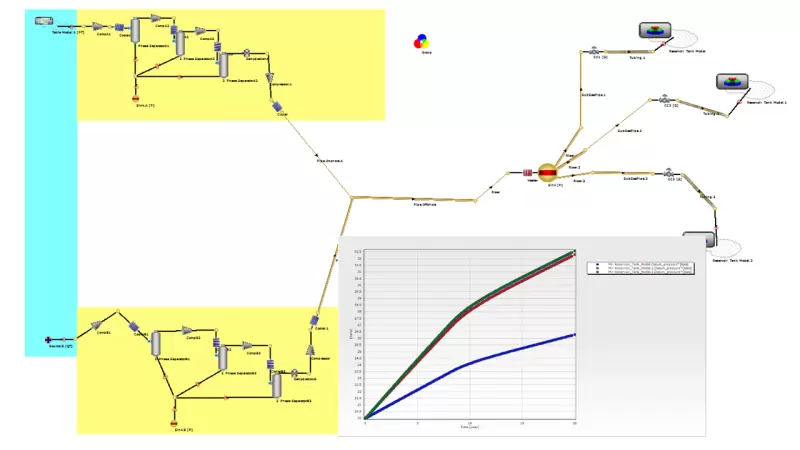

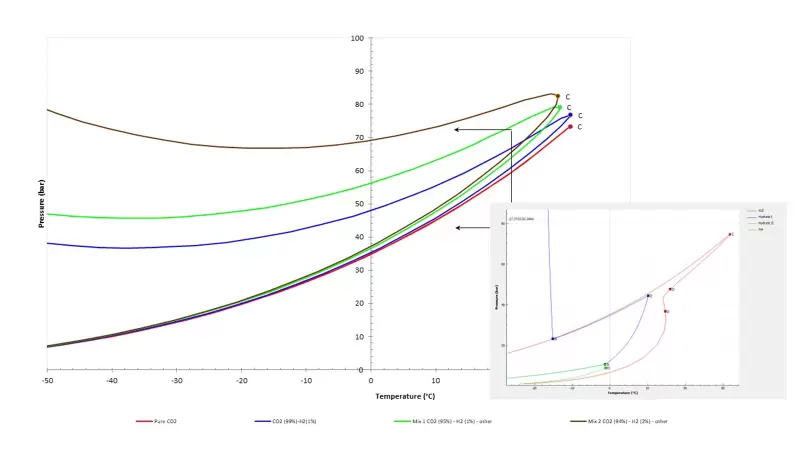

The KBC simulation software suite is an integrated portfolio of modeling and simulation tools, allowing to model production, processing, and energy utilities and carbon capture, transport, and storage, with a high level of accuracy and rigorous thermodynamic modeling, providing a complete solution to engineers, operators, and management looking to elaborate and execute the correct strategy for energy transition and decarbonization projects. Through high levels of accuracy and integration capabilities, KBC's simulation software suite enables the evaluation of risks associated with flow assurance, asset performance and integrity, and constitutes a trusted source of information in design and operations.