Easy Integration IIoT Protocols

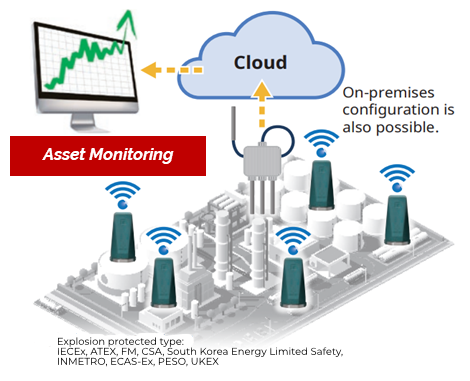

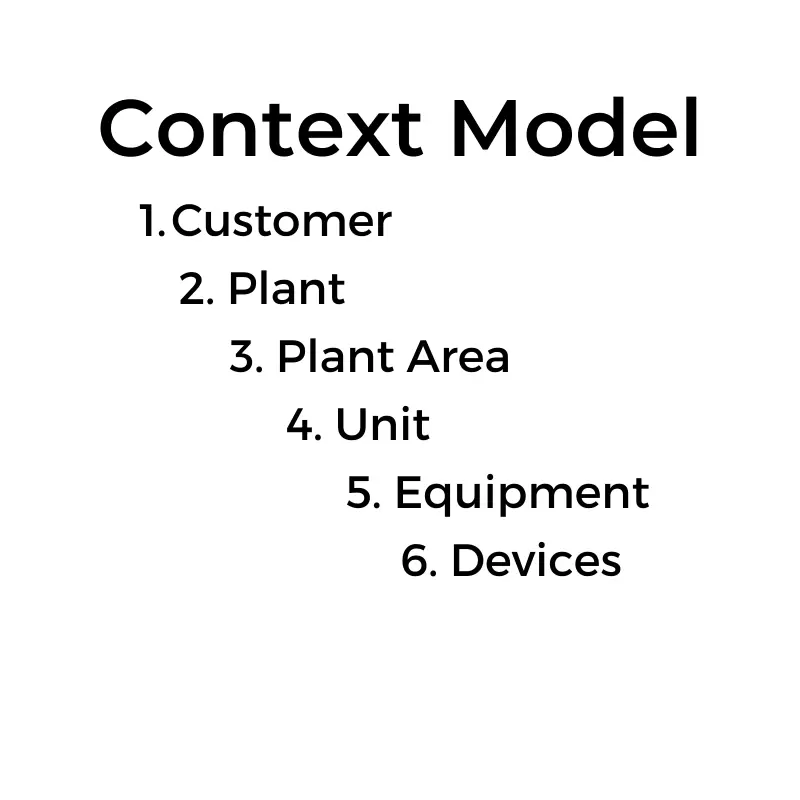

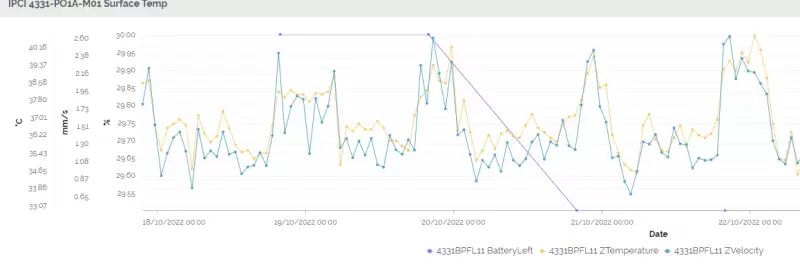

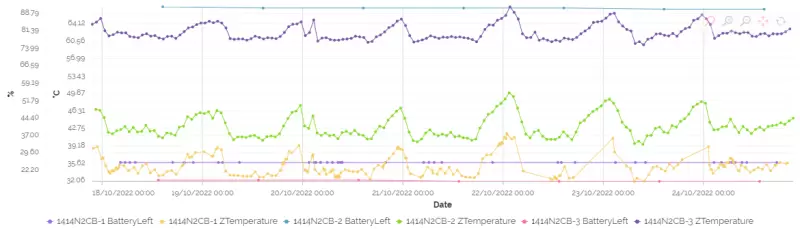

Take advantage of the tight integration with the Yokogawa Sushi Sensors, to route your equipment data from device to Gateway and on to the resource stores in the cloud. Easily integrate your IIoT sensors data using industry-standard protocols such as MQTT.