D HTR-SIM®

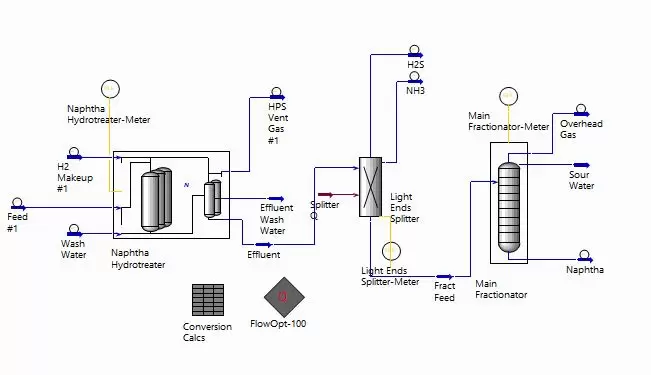

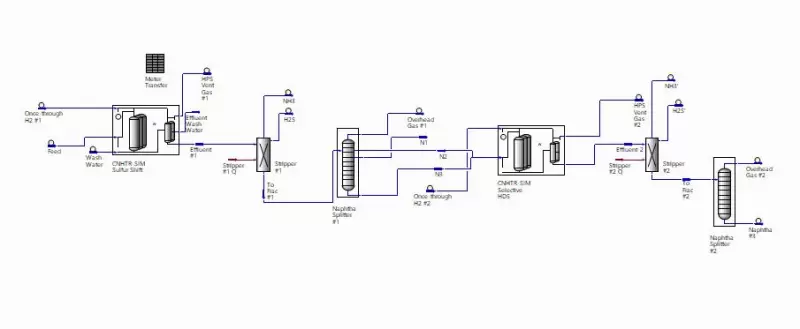

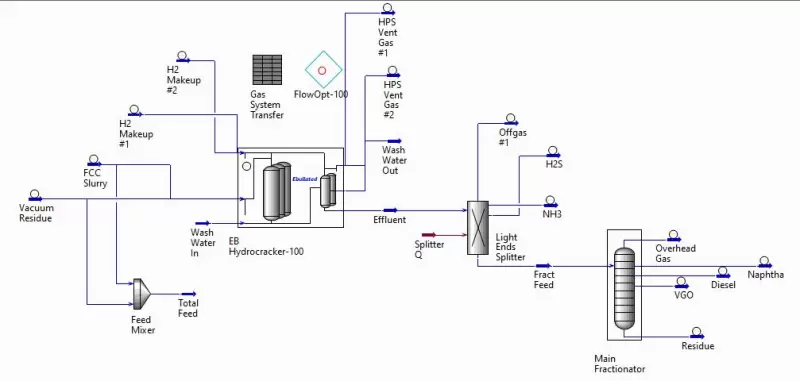

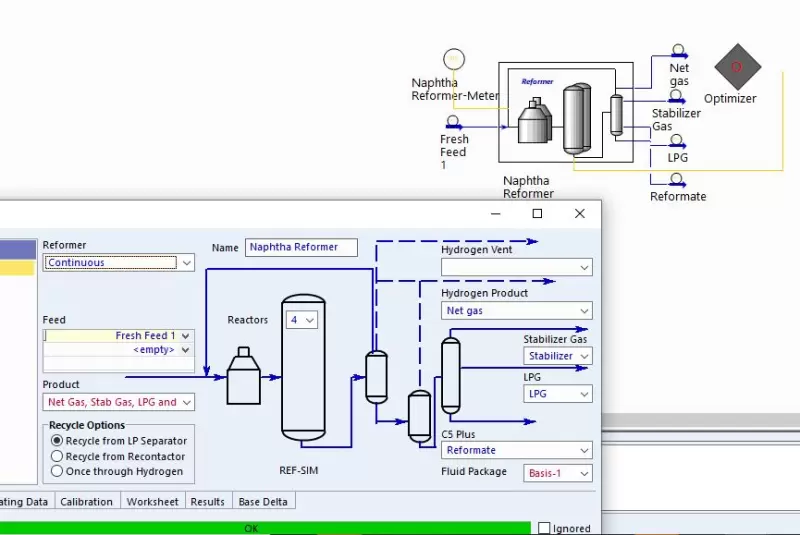

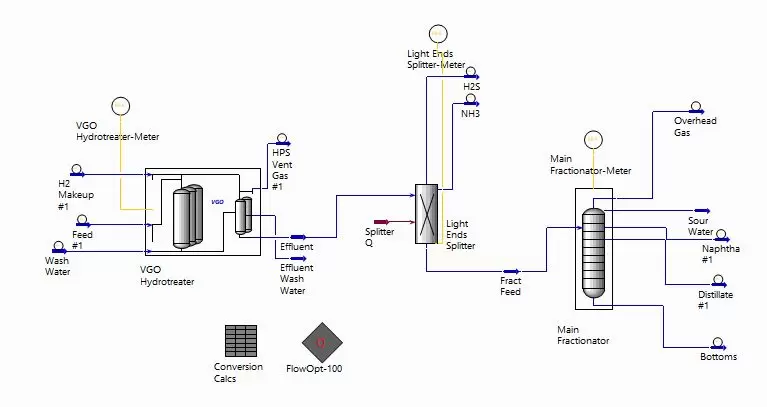

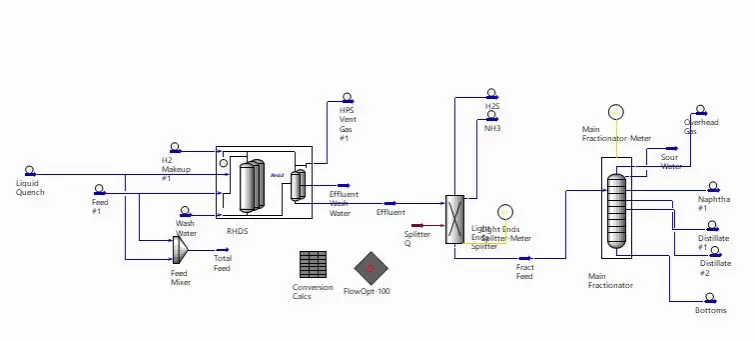

D HTR-SIM uses established first-principle kinetic expressions to model the key hydrotreating reactions including desulfurization, denitrogenation, olefin and aromatic saturation, naphthene ring opening and cracking. It also tracks and models the deactivation effects on the catalyst due to feed metals poisoning. The model supports methodology and internal kinetics to support modeling ULSD operations, supports pressure drop calculations across the reactor catalyst beds as well as poly-aromatic profile predictions.

In order to help our customers meet their decarbonization goals, KBC has also introduced a renewable mode in D HTR-SIM for hydrotreating fatty oils from plant and animal sources. Users can take advantage of the feed characterization to model TGLs and FAs into their hydrotreaters and simulate the heat effects, predict effects of oxygenates, balance hydrogen consumption and monitor diesel cold flow properties. The HDO reactor effluent can now be routed to an isomerization kinetic reactor within the same module to convert the n-paraffins to iso-paraffins and improve the cold flow property predictions. The model can handle co-processing and 100% bio-oil processing with flexibility of feeding bio-oils to multiple sections in the unit to stay on top of the industry updates to this technology.

We are proud to have been named finalists for the DHTR-SIM (Renewable mode) in the Gulf Energy Excellence Awards 2023 for Best Modeling Technology.