Scalable Solution for Performance Improvement

Comprehensive and consistent insights into an operating asset are often lacking or difficult to access due to issues with data quality/availability, limited access to knowledgeable experts, and siloed communication.

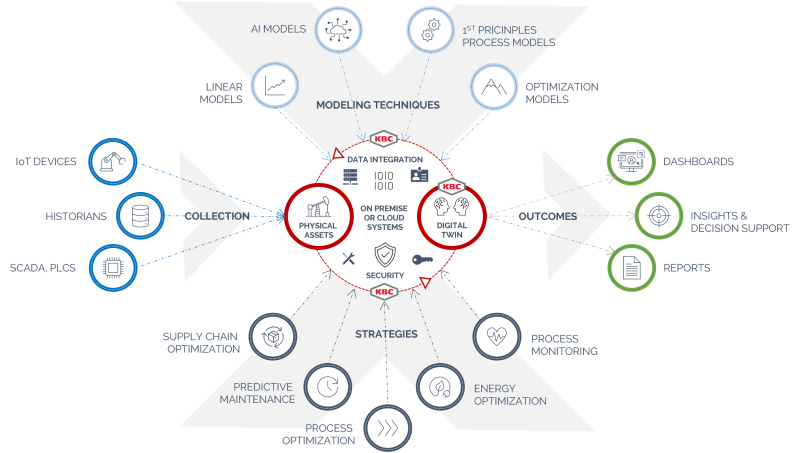

The KBC Digital Twin, with a process simulation/production model at its core, is a powerful tool to help design, monitor, troubleshoot, optimize, forecast, and plan single unit and full asset performance. It provides underlying performance information, automates the collection and validation of data, and delivers the analysis through visualization and reporting tailored to specific consumers.

Whether looking to perform asset monitoring, LP assurance, predictive analytics and/or equipment reliability and performance improvement, the KBC Digital Twin is a core component of workflow digitalization strategy, delivered 'on prem' or via KBC AcuityTM Industrial Cloud.