Refinery Increases Productivity

Visual MESA Production Accounting integrates with business management systems to automate tasks while enhancing business processes, team collaboration, and productivity.

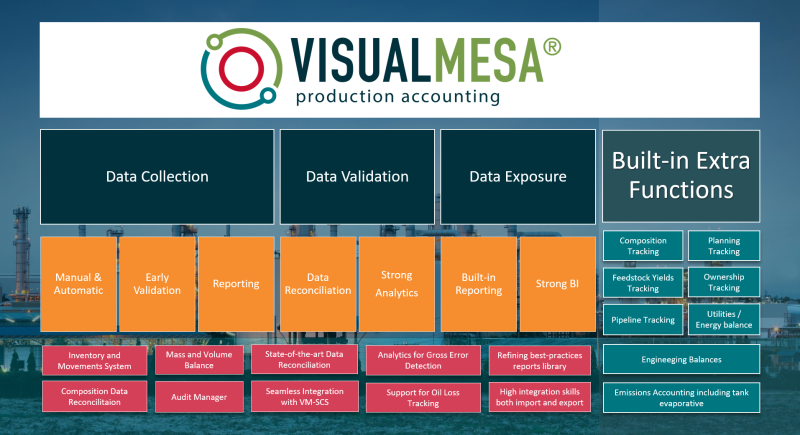

Visual MESA® Production Accounting software is the most advanced solution for production accounting, balance, and data reconciliation applications. For more than 20 years, our production accounting software has been the most widely used technology in Latin America, with a continuously growing global presence.

Refineries adopt renewable fuels to mitigate climate change and minimize greenhouse gases across the entire supply chain. Thus, high-quality, shareable data is a key asset for accurate and timely decision-making. Visual MESA Production Accounting delivers production accounting data through the world's best-in-class data reconciliation algorithm to support accounting systems ranging from basic to complex environments in oil and gas and renewable fuels. The result is a single version of truth serving as the facility's balance and loss control initiative.

Carbon accounting through reliable and transparent systems ultimately achieves transparency on the climate impact of companies.

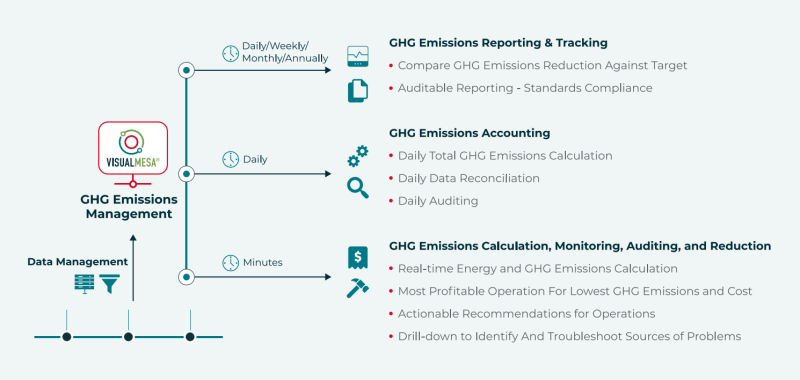

As a single version of the truth, Visual MESA Production Accounting is a key component of the state-of-the-art Visual MESA Greenhouse Gas Emissions Management solution and underpins the facilities material balance, loss control initiatives, and reliable data provider for auditable, official emissions reporting.

Visual MESA Production Accounting delivers a best-in-class approach to production accounting. It is a flexible, scalable, multi-purpose solution for production accounting as well as balance sheet and data reconciliation applications that houses a complete library of value-add functions.

Download Visual MESA Production Accounting Technology Summary

Visual MESA Production Accounting digitally manages and integrates scheduling and reconciled balance data into corporate systems. By creating a single source of truth between the asset and the supply chain, the oil and gas industry moves toward its digitalization goal of value chain optimization.