Use AI to automatically keep your digital twin models up-to-date to meet your production plans.

Find out more

Multiflash® 7.2 Service Pack 1 simulator is the next generation tool to enhance and simplify workflows for production and flow assurance engineers. It remains at the forefront of the digitalization wave and aims to optimize the entire energy and chemical industry.

With the increasing attention of carbon capture, usage and storage (CCUS) as well as hydrogen production, the industry-wide challenge to shift from high- to low-carbon technologies escalates. Increasingly, simulation software faces the challenging aspects of production, transportation, usage and storage of gas systems that exhibit complex and unusual phase behaviors and phase properties, such as CO2 or Hydrogen dominated systems.

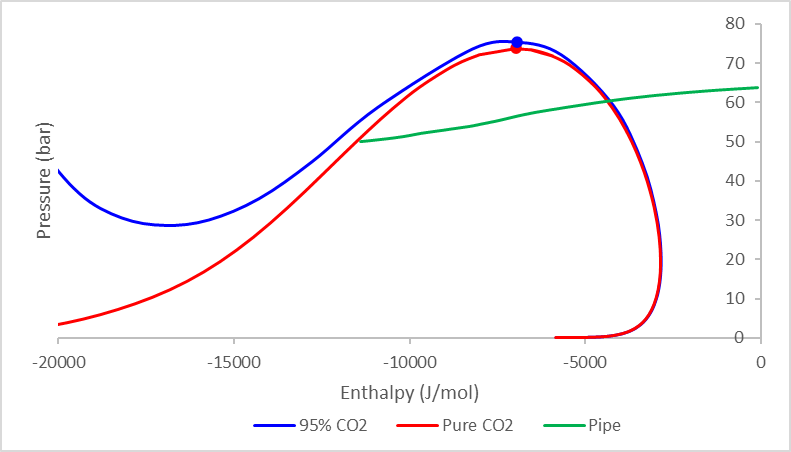

When the system is dominated by one main compound (e.g. CO2 with impurities), it behaves similarly to a pure compound. Systems like this may abruptly pass from one to two- or three-phases in a short temperature and pressure range. With a sudden change in properties and number of phases (e.g. gas phase suddenly turning into a liquid phase as the temperature drops just 1-2°C), challenges arise due to instabilities and/or slowdowns of either dynamic or steady-state thermo-hydraulic simulators (Figure 1, right). This is due to the fact that simulators are very often based on a PT (pressure, temperature) formulation. In PT representation, the VLE (Vapour-Liquid-Equilibrium) of pure compounds or quasi-monodisperse systems reduce to just a very narrow region, or a single line, making simulations across the VLE extremely challenging (Figure 1, right).

Figure 1. Gas-Liquid saturation line for pure CO2 (red) and gas mixture with 95% of CO2 (blue) in Pressure-Temperature plane. The overlayed pipe profile (green) intersects the saturation line and follows its path in the final part of the pipe.

Ultimately, design challenges emerge. The risk of incorrect assumptions, excessive margins, or incorrectly representing the behavior of the operating asset results in lack of control and optimization.

Simulations are greatly improved when switching from a PT formulation to a PH (Pressure, Enthalpy) formulation. This change is based on the solution including the phase equilibrium at fixed pressure and enthalpy rather than a fixed pressure and temperature. In the PH plane, the two-phase coexistence region spans across a wide range of pressure and enthalpy, even for single compound systems, avoiding the abrupt changes that would be observed in a pressure and temperature representation (Figure 2, left).

Figure 2. Pressure-enthalpy representation of the same systems as Figure 1. In the PH plane, the pipe profile crosses the Gas-Liquid coexistence region with no abrupt change of properties or amount of the coexisting phases, reducing the risk of instabilities.

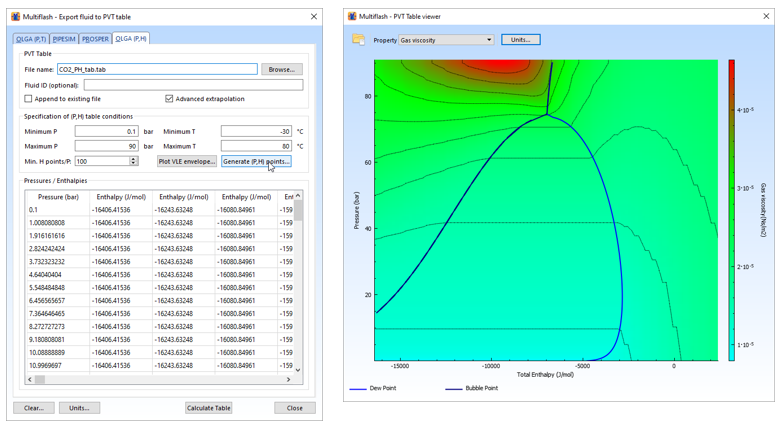

Multiflash 7.2 Service Pack 1 includes the possibility of creating look-up tables on a PH grid, similar to the PT grid functionality (Figure 3, right). This allows OLGA 2021.1 to simulate these systems using a PH formulation even for standard non-compositional simulations, conjugating the speed of the tables with the stability and accuracy of the PH formulation. This, ultimately, guarantees the correct representation of production and transportation of a single compound and quasi-monodisperse gas systems.

Figure 3. Left - the PH table generator in Multiflash 7.2 Service Pack 1 software. Right - Multiflash table viewer visualizing a pure CO2 system in the PH plane.

In conclusion, Multiflash 7.2 Service Pack 1 software enables the operator to make a significant impact on plant performance. Specifically, it optimizes work processes by increasing the effectiveness and efficiency of the engineering process. This effort eliminates potential sources or errors due to the use of inconsistent fluid properties throughout the various design and project execution steps. In addition, the Multiflash 7.2 Service Pack 1 simulator allows modelling of multi-phase systems that exhibit the coexistence of several fluid and solid phases. In turn, this provides an integrated and reliable solution for production optimization and forecasting as well as handling potential flow assurance or equipment availability issues.

For more information or to install Multiflash 7.2 Service Pack 1 software, please contact software@kbc.global