Decarbonization

Predict the physical properties and phase behavior of complex gas mixtures in carbon capture, utilization and storage, hydrogen production and transport, and other applications.

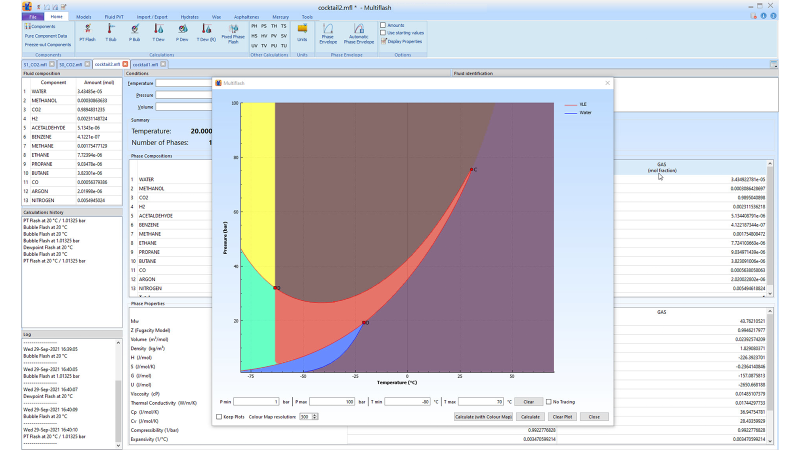

To increase operational efficiency, Multiflash® , a comprehensive PVT (Pressure, Volume, and Temperature) modeling and physical properties software, empowers engineers to predict the phase behavior and transport properties of complex fluids in oil and gas, refining, petrochemical & polymer, energy, and process industries.

Fluid modeling is carried out at various stages in design and operations. However, the lack of appropriate models and consistency across disciplines often causes delays, uncertainties, and costly mistakes. While this situation leads to excessive CAPEX/OPEX, it may also cause health and safety hazards and catastrophic damages to facilities.

Multiflash supports your organisation along its digital transformation and transition journey toward net zero by:

Pontem Analytics, a consultancy working to support clients in the energy sector, needed a good understanding of the fluids they were working with to drive the design, concept, execution and operation of a project throughout its life of field. Multiflash is pivotal in helping Pontem Analytics understand fluids at an early stage of a project to address challenges the project will face. Using Multiflash with the Excel add in and other interfaces such as the new Python API, has allowed Pontem Analytics to write scripts to automate certain processes and run thousands of calculations, making tasks much faster and easier and generating insights that can feed into the engineering work.

Pontem Analytics was the first to use Multiflash in the cloud. By accessing Multiflash through the REST API they produced a dashboard enabling their clients to make flow assurance calculations on demand to mitigate risks such as the formation of hydrates in their assets. Through the web application, the user could interact directly with Multiflash to run calculations for risk evaluation at operating conditions, and gain a better understanding of the potential operating scenarios, giving engineering and production teams confidence in the production plan.