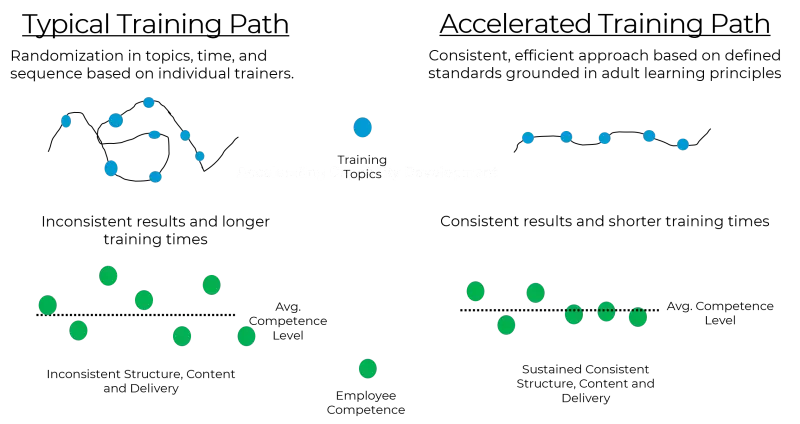

Changes in staff performance put your operations plan and safety performance at risk. This variation in competency and performance levels is typically caused by substandard learning materials, inconsistent training practices, poor learner engagement, and a lack of performance management.

The challenge is to unlock the ambition of the younger generation joining your shift teams, accelerate capability transfer through structured pre-learning and blended learning techniques and shorten the time required off shift for classroom training. Improve reliability, capture margin, and reduce costs by developing shift team practices, operators who take ownership of equipment care in the field, and optimize your operations at the console.