The Virtual Flowmeter Use Case

Operators have access to relevant data from the producing asset, including operating pressures and temperatures at different points of the production facilities. However, flow rate is often only available as cumulative data for an entire asset, through a direct measurement of gas, liquid and water volumes produced at the separator. Unless Multi-Phase Flow Meters are installed in every well and facility, no information is generally available on the amounts produced by each specific well. Furthermore, no detailed information on the fraction of each phase is generally available.

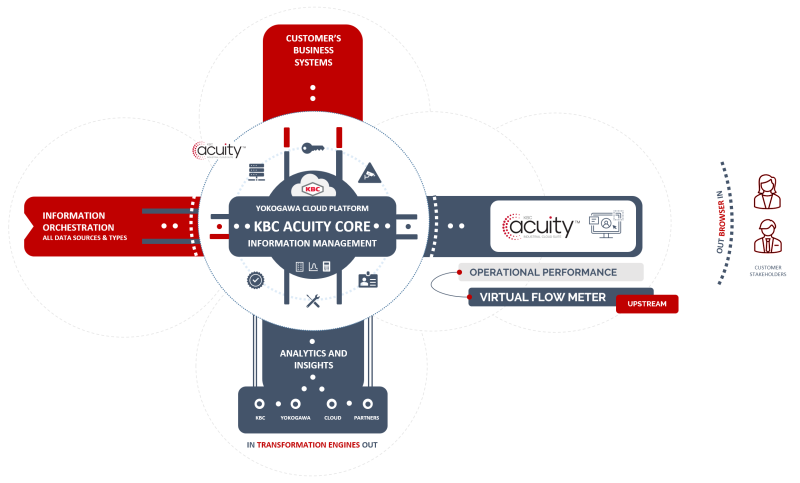

The integration of operating data acquired by KBC AcuityTM Operations Monitor and KBC process and production simulators, enable real time or look-ahead predictions of specific well production. This allows early and informed decision making to provide valuable KPIs for production optimization and setting of operating targets.