Explore practical solutions to green hydrogen production challenges.

In the race towards global decarbonization, green hydrogen has emerged as a key player. But how can we ensure the safety and efficiency of its production? The answer lies in dynamic simulations. Let’s explore why these simulations are invaluable in the green hydrogen industry.

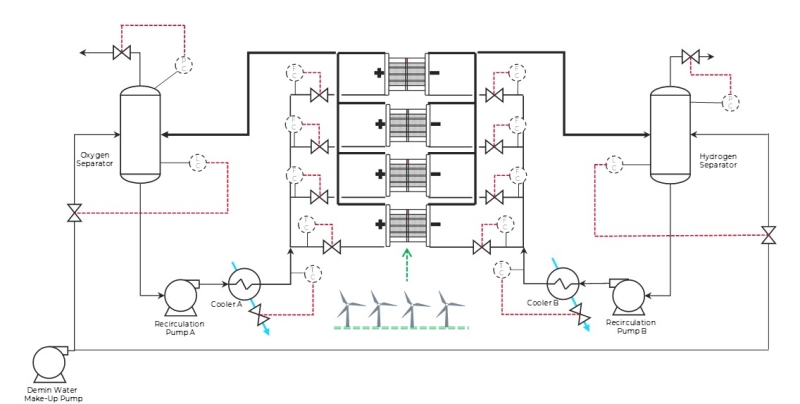

Green hydrogen is produced through electrolysis, powered by renewable energy sources such as solar, wind, and hydropower. While clean, this process involves complex systems that require careful management and optimization – a challenge where process simulators offer many benefits, as shown in Figure 1.

Pressure relief systems are critical for hydrogen production, particularly during overpressure events. Dynamic simulations allow you to examine possible causes of overpressure - such as closed outlets, cooling failure, abnormal energy input, fire contingency, and more - while avoiding overly conservative designs for relief and flare systems, as shown in Figure 2. By providing an exact method to calculate relief loads, simulations enhance our understanding of overpressure causes and ensure compliance with API Standard 521.

In a bank of electrolyzers that run on renewable energy, such as wind, Figure 3 shows how dynamic simulations effectively distribute power.

For instance, a bank of four 25 MW electrolyzers showed better efficiency when operators adjusted water feed rates for each unit instead of applying the same rate to all. This approach reduced operational variability, cutting water use by 25% and energy consumption by 15%.

Dynamic simulations enable you to keep green hydrogen production stable and reliable. By identifying overpressure scenarios, assessing assets in real time, and configuring efficient process controls, they optimize operations while Bringing Decarbonization to Life®.