Press play to listen to this blog.

Green hydrogen (H2) works. So, why do so many projects stall after the pilot phase?

It’s not because technology fails. It’s because scaling green H2 forces operators to rethink how energy systems, markets, contracts, and operations interact.

In this post, we’ll walk through the four questions industrial operators are really asking — and what it takes to turn green H2 from a regulatory checkbox into a bankable, scalable asset.

For years, H2 flew under the radar. Today, it’s in the spotlight.

Traditional production, especially steam methane reforming, carries a high carbon footprint and is now subject to tightening emissions reporting and disclosure requirements. As transparency increases and carbon exposure is priced in, H2 is no longer just a utility. It’s a line item in the balance sheet that impacts compliance, cost, and competitiveness.

On paper, green H2 looks straightforward. In practice, scaling it is not.

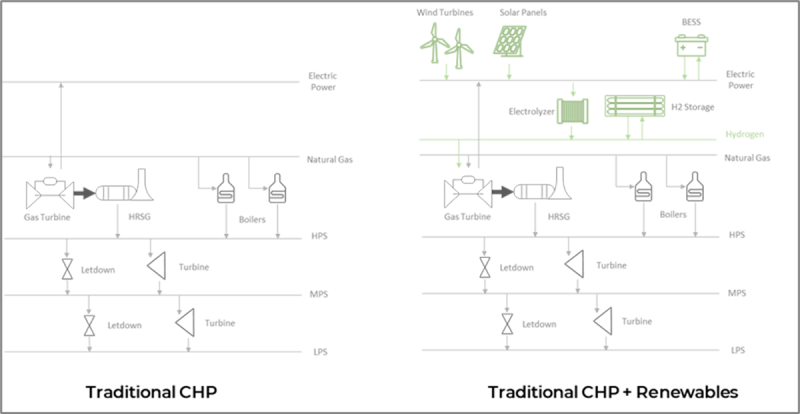

Renewable power is variable. Electrolyzers are capital intensive. Existing combined heat and power (CHP) and grid infrastructure were never designed for this level of complexity or coordination, as shown in Figure 1.

Add in the need for reliable demand contracts and transparent certification, and pilot programs begin to stall. Costs rise. Performance suffers. Momentum slows. Not because ambition is lacking, but because integration is.

This is where integration and optimization make the difference.

Viable projects treat green H2 as part of a connected energy system, not a standalone asset. Think orchestra, not soloist.

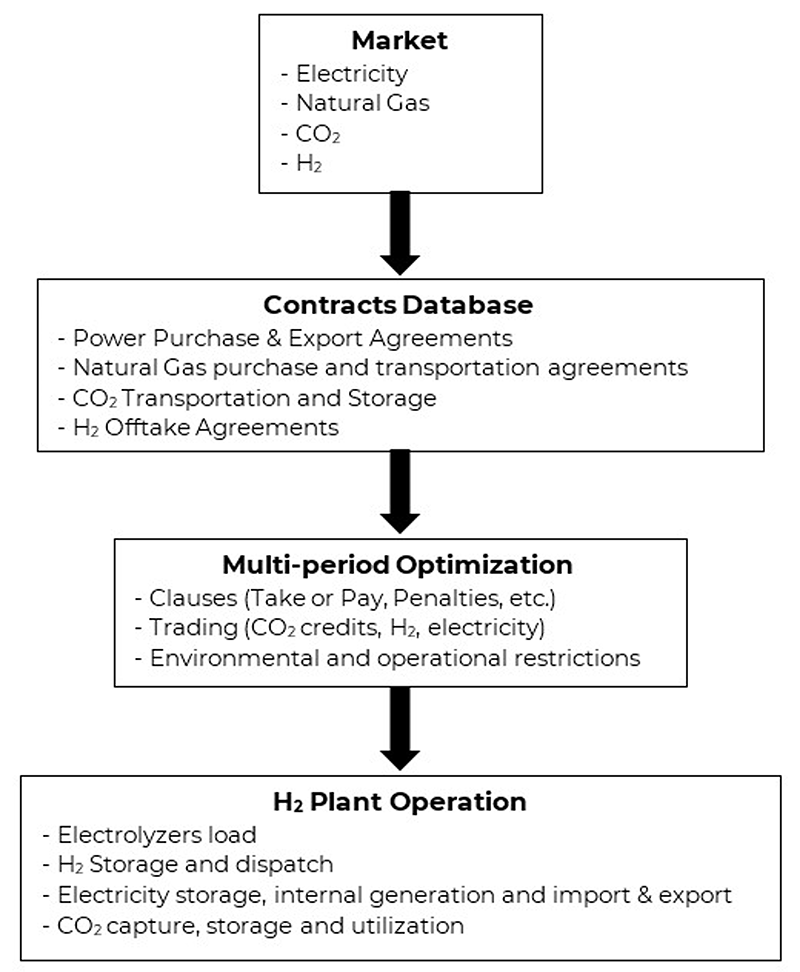

Real-time and multi-period optimization align H2 production with electricity prices, renewable availability, and downstream demand. Viability depends on respecting contract realities — power purchase agreements, take-or-pay clauses, and H2 offtake commitments — which act as hard constraints alongside market signals. Storage — batteries or H2 tanks — adds flexibility. It buffers volatility instead of amplifying it.

At the design stage, simulation helps teams make the right decisions before steel is in the ground, reducing CapEx risk and avoiding redesigns later, as shown in Figure 2.

Visual MESA® Energy Management System (VM-EMS) brings these pieces together — aligning design, dispatch, and decarbonization - turning volatility from a liability into a lever.

Clean H2 only delivers value if it can be trusted.

Certification frameworks, auditable emissions accounting, and real-time monitoring are essential for regulatory compliance and market credibility. Automated, cradle-to-gate emissions tracking ensures H2 claims stand up to scrutiny.

Figure 3 shows how tools like VM-EMS connect operational decisions with emissions outcomes, providing a single source of truth for both performance and proof. Dashboards give teams visibility into carbon intensity and cost, hour by hour, decision by decision.

Scaling green H2 isn’t a technology problem. It’s a systems orchestration problem.

Success depends on integrating optimization, simulation, certification, and operational readiness from day one. It requires the skills to run these systems confidently.

Operators that get this right won’t just meet regulations. They’ll turn complexity into advantage and truly start Bringing Decarbonization to Life®.

This blog post was based on the EnviroTech article Green Hydrogen at Scale.