Delivering Value

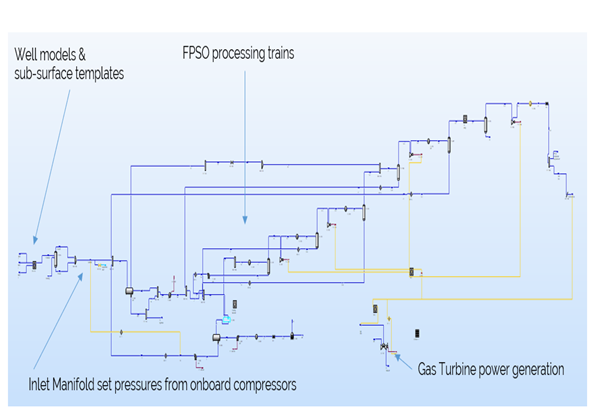

Integrate and optimize Oil & Gas assets from reservoir, through wells, gathering systems, processing facilities (offshore, onshore, FPSO) to gas plants, export pipelines and LNG plants through KBC’s proven expertise and technology. From offline Integrated Asset Models to online Digital Twins of an Oil & Gas asset and from start up and shut down to dynamic flow assurance surveillance, continuous value is gained from KBC solutions.

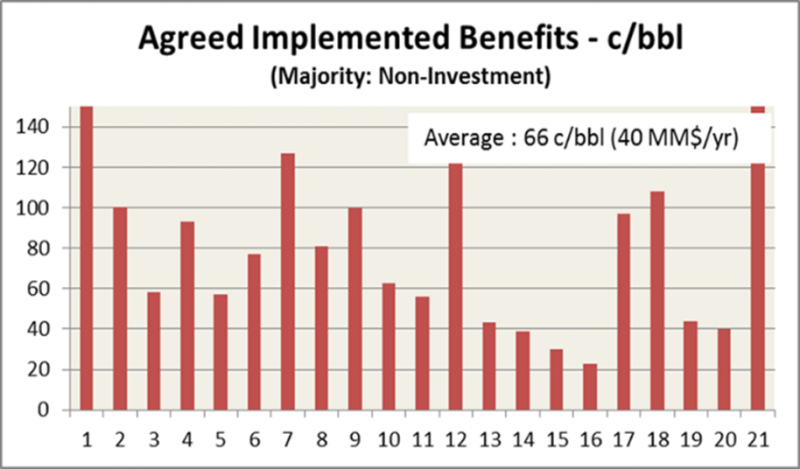

In Refining & Petrochemicals, KBC is a world leader in profit improvement programs, yield and energy studies and reliability and maintenance, offering a wide range of consulting expertise and technology solutions including the world’s only full refinery wide simulator that now includes carbon intensity and decarbonization capability.

In Chemicals, Power, Renewables and other vertical industries KBC is able to leverage its knowledge in process optimization to offer innovative and novel solutions to process optimization challenges.