The energy sector is undergoing a digital transformation. But what exactly is digital transformation and why is it important? According to Inc.com, digital transformation refers to the way in which companies transform their businesses through technology. Digitalization has infiltrated almost every aspect of the market, from exploration through refining to petrochemicals and polymers.

Each year, energy companies spend a significant amount of money on process simulations and other predictive analytics tools. In fact, Lloyd's Register reports that 57 of the world's 100 largest oil and gas companies are using, or have plans to use, predictive analytics. Thirty-four of these, report a positive impact from predictive analytics use to make better and faster decisions that improve facility performance, productivity, and increase profits.

Already a game-changer in the industry, KBC's award-winning Petro-SIM® digital twin has revolutionized the way of unit monitoring technology in Oil Refining and will revolutionize the O&G and Petrochemicals industries next. Business teams can collaborate seamlessly to ensure a reliable operation of the unit and improve refinery profit margins with real-time data-backed decision-making.

During a KBC webinar on the evolution of process simulation, attendees from Oil Refining were asked to identify their biggest challenge with software. The intel gathered by KBC and its parent company, Yokogawa, gave clear results. Forty percent of attendees identified the lack of ability of a model to automatically match more current operation and predict new operation as the biggest drawback of process simulation.

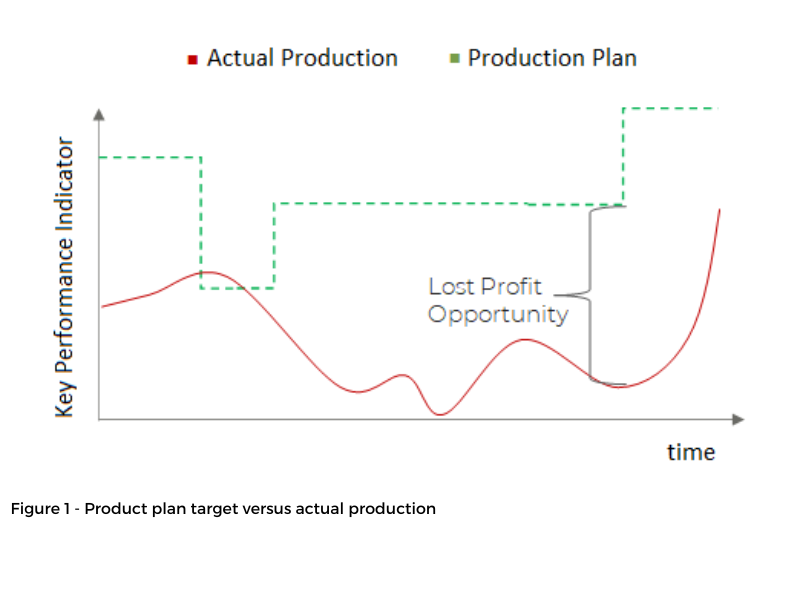

Maintaining models and updating software require time and expertise, from extensive data analysis to laboriously updating the models. This situation leads to lost profit opportunities and inaccurate production plans, as depicted in Figure 1.

The Petro-SIM simulator's latest Automated Model Maintenance feature is a cloud-based solution that takes simulation modeling to a whole-new level by automating and simplifying model maintenance.

This web-based solution provides health indicators and supporting evidence for clients to decide with confidence whether to update the models to minimize lost profit opportunities. Furthermore, the solution automatically flags and excludes poor data from the analysis. This solution is being extended to include automated model updates, ensuring Petro-SIM high fidelity models stay current and continue delivering value across the organization. Following are five benefits of this AI-driven automated model maintenance solution.

Enables Advanced Analytics

Oil refineries can accelerate their digital transformation. This solution uses cutting-edge AI and ML tooling from KBC’s partner C3 AI, a proven Enterprise AI company in the industry, to deploy KBC proprietary algorithms with the Petro-SIM digital twin as a step towards creating innovative simulation modeling and making simulation software more accessible. Finally, this solution will use AI and ML to improve current planning tools and processes.

Delivers Value

Trusted data and automated up-to-date models boost operational efficiency and business decision-making. The key benefits of this AI-based solution are that the health of the models used in the Oil Refining value chain optimization, are automatically monitored, and kept in sync with actual. The solution provides health indicators and supporting evidence for clients to decide with confidence whether to update the models to minimize lost profit opportunities. Furthermore, the solution automatically flags and excludes poor data from the analysis. This solution will soon also enable model updates, ensuring Petro-SIM high fidelity models stay current and continue delivering value across the organization.

Improves Speed and Performance

As cloud-based, AI solutions become more mainstream, they will be able to scale across multiple assets and sites and evolve with other applications. Currently, monitoring models and running many calibrations and cross predictions is both computing and engineer time- intensive. By providing this AI/ML driven solution in the cloud, KBC will be able to serve clients better, since it gives them more performance advantages and frees up local computing resources while the application runs in the cloud.

Optimizes Resources

By automating the model maintenance work processes, engineers can focus their time on opportunities offering greater value. In addition, the Automated Model Maintenance solution has been purposefully designed to be semi-automated so users can interact at each stage of the process. The goal is for clients to easily adopt the recommendations and understand the results. Eventually, the solution will allow a fully closed-loop workflow.

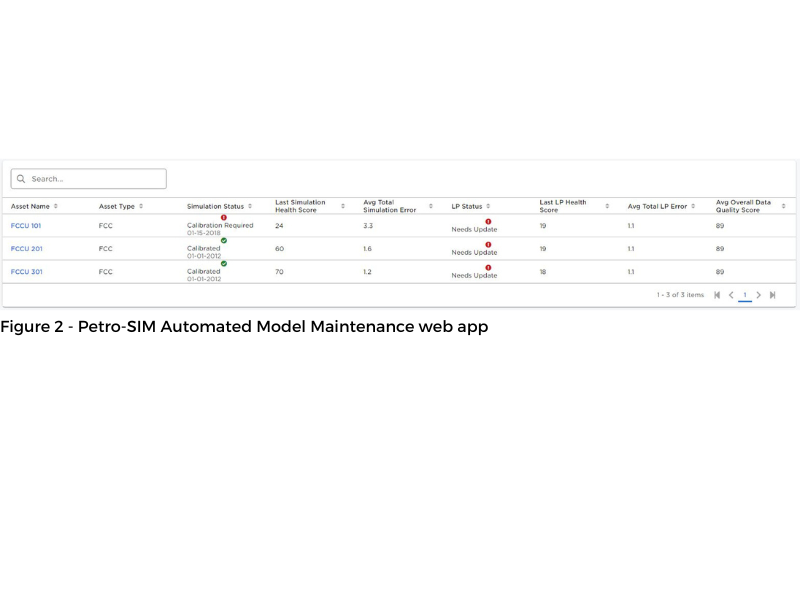

This cloud-based, AI-driven solution, is a subscription-based service powered by the Yokogawa Cloud platform designed to help customers save money. A user-friendly web application, that clients can easily access reader-friendly reports and subscribe to notifications related to all or specific units across multiple sites. For instance, clients can quickly get a simulation model health status, LP sub-model health status, and more for each asset as depicted in Figure 2. In addition, the Petro-SIM Automated Model Maintenance web application is conveniently accessible 24/7.

The Bottom Line

Managing large-scale process simulation models traditionally is a time-consuming, costly, and repetitive process carried by skilled resources. A lack of automation in model maintenance poses major challenges, such as determining the cause of deviations, choosing the right data to update the model, and tune and validate the simulation model to be in sync with actual.

KBC's Petro-SIM Automated Model Maintenance addresses all of these challenges. This solution links to the Petro-SIM digital twin at the client's premises, automatically pushes the cases data to the cloud, and then uses AI-based machine learning technology to determine whether to update models. Future releases of the solution will automatically generate and validate the models against more current plant data. Moreover, the service is scalable to accommodate clients' growing simulation models, digital twins, and applications over time.