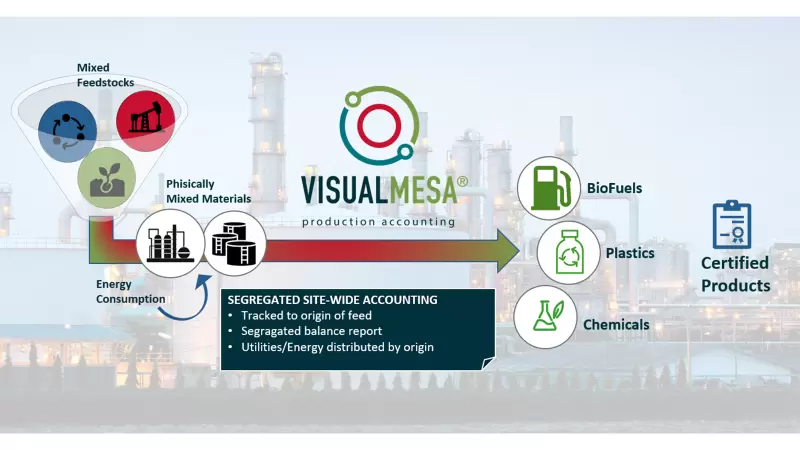

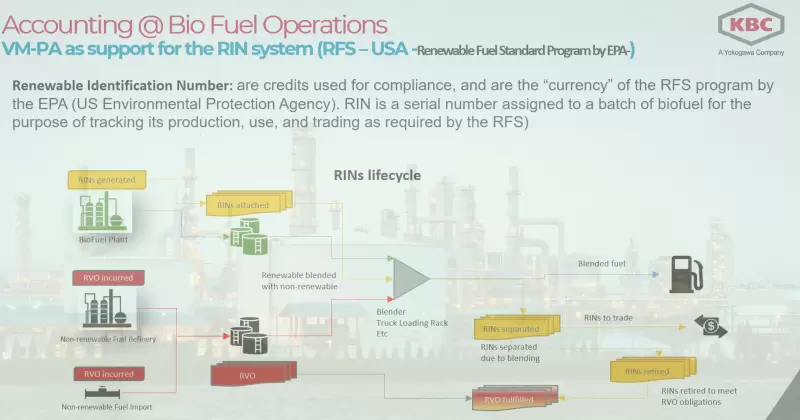

KBC's Visual MESA Production Accounting model represents the mass balance of the site covering the assets and operations, including receipts, shipments, storage tanks, process units, and fuel consumptions. This model is reconciled daily and allows the generation of standard accounting reports, including inventory, material balance, net production, hydrocarbon losses, receipts, shipments, etc. On top of the accounting, balance, and reconciliation functions, as a core functionality relevant to renewable/tolling operations, the accounting model allows tracing Carbon Index (CI) and products back to the origin of feed (both by feedstock type (i.e., yellow grease, white grease, lard, corn oil, palm oil, sunflower oil, etc.) and by tolling ownership (i.e., owner 1, owner 2, etc.) if applicable). In addition, this information can be exported to other applications for CI credit calculations and transactions.

Visual MESA Production Accounting software is the most advanced solution on the market for production accounting, balance and data reconciliation applications.