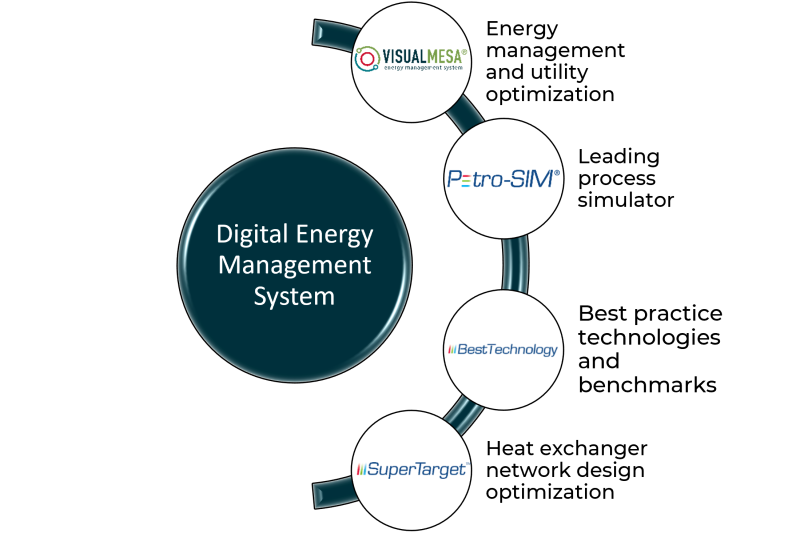

Comprehensive Suite of Trusted Modeling Tools

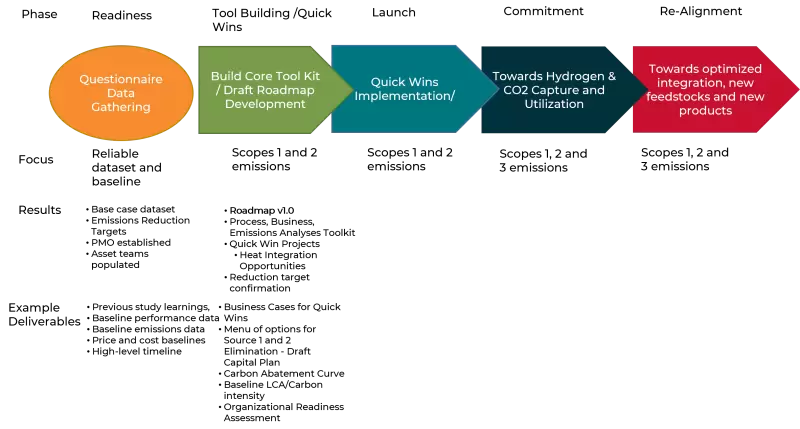

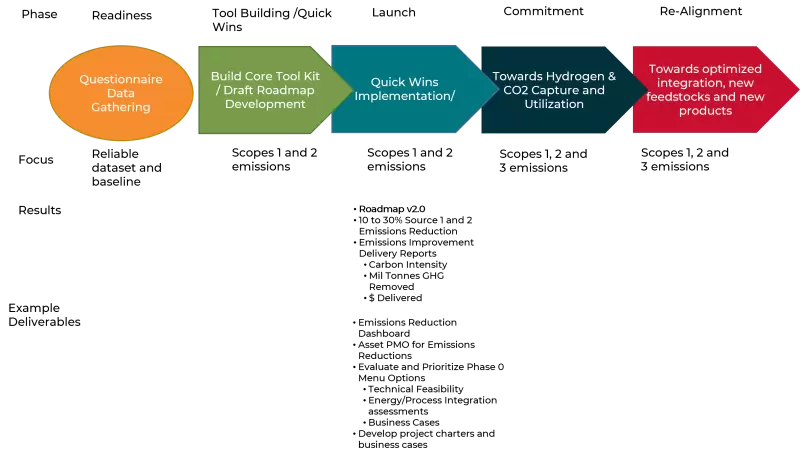

KBC brings a detailed and rigorous project methodology that allows a better understanding of the source and cause of all Scope 1 and 2 emissions from assets down to the equipment level. Mapping the process and energy demand down to the heater, boiler, and turbine level, for example, allows the emissions to be quantified, prioritized, monitored, and then eliminated using a range of solutions such as electrification, hydrogen firing, reduced flaring, reduced energy usage and through carbon capture. Dashboards synthesize and distribute the information and targets to allow drill-down analysis remotely and in real-time.